Topic

Automation

Published

August 2024

Reading time

14 minutes

IIoT at a Tipping Point

What needs to change for it to deliver real value and why we think now is the time

IIoT at a Tipping Point

Download ArticleResearch

Introduction

You’ve probably already heard about the fourth industrial revolution, or Industry 4.0, which has been described thoroughly by Klaus Schwab as a fusion of technologies that is blurring the lines between the physical, digital and biological spheres. It is a revolutionary phase in the digitization of the manufacturing sector.1 We’ve been spending time looking at what we believe to be the central nervous system of Industry 4.0, the Industrial Internet of Things (IIoT).

For humans, the central nervous system acts as a sophisticated communication network, constantly monitoring our environment and coordinating our organs responses. But factory operations didn’t (and many still don’t) have such a nervous system, that is… until recent years. IIoT is essentially the nervous system of operations, enabling industrial environments to be smarter.

The idea of machines being able to interact with each other and share data may have sounded crazy a few years back, but IIoT has changed the status quo. The idea was that through the adoption of IIoT, manufacturers could finally make use of the large amounts of data produced by machines in industrial settings. This has allowed for smarter and more sophisticated operations – resulting in major efficiency gains. In fact, in our Industrial Intelligence piece we attempted to quantify these efficiency gains.2 Companies using intelligent software, such as IIoT, see improvements not just in energy use (-24%), but also in productivity (+52%), labor costs (-32%) and manufacturing costs (-26%).3 Taking all of this into account, we estimate that the global manufacturing sector could save ~25% of its COGS.4 The resulting global savings would be equivalent to the GDP of France!

Industrial Intelligence

Industrial Intelligence means unlocking all the operational data that these organizations generate and leveraging it to drive efficiency, increase returns, and meet sustainability targets. The “Internet of Things” (IoT) is a major component of being able to capture this data. Despite this, the uptake of these solutions has not lived up to expectations.

While the need for Industrial Intelligence has never been stronger, these modern technologies have never quite taken off. We will highlight several reasons for this below, as well as discuss why we feel that this may be changing in our opinion. There is still enormous upside to be captured.

The promise of IIoT

The Internet of Things (IoT) is a network of physical objects connected by the Internet through sensors and software. This can be as simple as controlling a thermostat on your mobile device or as complicated as automating inventory management for a large warehouse. Any device that can connect to the internet and communicate information from an object can become an IoT asset.

IoT originated in the 1990s when computer engineers were adding sensors and processors to everyday objects, with RFID tags being the first to track expensive equipment. Currently, computer chips are inexpensive and combining them with rapid bandwidth telecommunication has led to billions of devices being connected to the internet. By 2025, there will be an estimated 40 billion IoT devices connected to the internet ready to transmit and receive data.5

What exactly is IIoT?

The Industrial Internet of Things (IIoT) is IoT applied to industrial sectors and applications. Using smart sensors and actuators, IIoT can improve manufacturing and industrial processes. For example, one of Nvidia’s leading manufacturing partners has been able to use IoT data to reduce end-to-end cycle times by 50% and defect rates by 40%.6

One founder pointed out that whilst you cannot have IIoT without IoT, the two have distinct features. A key differentiator between IIoT and IoT is the number of devices needed and the amount of data collected. With IIoT, the devices are fewer, but the volume of data collected is much higher. In addition, devices within IIoT are much more heterogeneous.

The urgent need for IIoT

Traditionally, visibility within factory operations was often limited due to outdated processes and a lack of access to data. Organizations would know what assets were in their factories but any data on the status, location or performance of these assets was limited. IIoT enables increased operational efficiency and productivity by addressing:

Downtime: Equipment failure can have a significant impact on productivity, which may limit revenue. Unplanned downtime is estimated to cost businesses as much as $260,000 per hour or $50 billion each year.7,8IIoT enables manufacturers to have access to predictive maintenance technology, which decreases the risk of unplanned downtime and thus minimizes the corresponding revenue losses. Deloitte research suggests that companies that implement predictive maintenance can expect to see a 10%-20% reduction in maintenance costs, a 20%-25% reduction in equipment downtime and a 5%-10% increase in production capacity.9

Energy use: The use of IoT in manufacturing can reduce energy usage. For example, Armal, a manufacturer of portable toilets, found that real-time IoT monitoring of the production line helped reduce the energy costs of machinery by almost 40%.10

Labor Costs: While automating manual processes using IoT systems requires an up-front investment in technology, those expenses are steadily recouped in saved labor costs over time. In addition, by introducing IIoT, workers are freed up of repetitive tasks.

Worker Safety: The National Safety Council estimates that workplace injuries cost businesses more than $161 billion per year.11 Workers in construction, manufacturing and warehousing experience some of the highest rates of injury and real-time monitoring and alerts through IIoT can reduce the number and frequency of workplace accidents.

It has been technologically possible to implement IIoT-based use cases since the early 2000s. However, we found that multiple manufacturers either have no IIoT system in place or have attempted to build from scratch through internal dev teams using AWS or Google frameworks. We think that this is changing. What we are witnessing now is the opening of completely new possibilities for implementing sophisticated, innovative use cases in a streamlined way.

Companies miss a big opportunity to quickly improve safety, sustainability, and efficiency when they attempt to build IIoT solutions from the ground up. Software and end-user applications are available today that offer flexibility, connectivity and scalability across systems, networks, protocols, and devices ... and they can be up and running in days. That's exciting as it means companies can unlock their machine data faster and start more advanced IIoT initiatives like Edge AI or Intelligent Video Analytics sooner.”

Aaron Allsbrook, Chief Technology Officer & Co-Founder, ClearBlade

Unlocking the benefits of IIoT

Falling data storage and hardware costs, along with expanded internet connectivity promised unlimited gains from IIoT. The expected result of this progress was that it would be easier for IIoT to be implemented at scale. Given the magnitude of the cost decreases and spread of connectivity, it’s easy to see why:

- People had hoped that declining data storage and hardware costs would make IIoT more accessible. In the early 2000s, storing 1GB of data would cost more than $500. Today, 1GB of data can be stored for 4-7 days for as low as $0.02.12

- In addition, smaller and cheaper sensors, chips and communication modules were expected to make IoT devices more affordable and easier to integrate into various applications. In the early 2000s, the average unit price per sensor was more than $1.30. Today, this price has fallen to less than $0.50 per sensor.13

- Lastly, the expansion of internet connectivity was also predicted to trigger meaningful growth in the adoption of IIoT. Enhanced coverage and wider adoption of technologies like 5G, Low Power Wide Area Networks (LPWANs), and satellite connectivity are enabling more devices to connect and transmit data seamlessly. The growth of the number of 5G networks across multiple industries was predicted to result in a meaningful increase in the number of IoT devices, and hence both are considered beacons of the Fourth Industrial Revolution.

Despite all of this, IoT has failed to deliver on its promises. Much of the anticipation surrounding IoT has been nothing more than hype. Below are what we believe to be four major reasons why the adoption and success of IIoT has stalled:

Aligning technology with organizational needs: IoT has failed in the past due to players trying to piece things together haphazardly in the cloud. It turns out that what you need for IoT is not necessarily the same as what you’ve built in the cloud. Consequently, the IoT market has been mired in build-versus-buy for the past decade. We believe that this is changing. Deployment remains tricky, but there are more guidelines and how-to’s than ever before. Manufacturers are taking a more cautious approach to how they implement IIoT solutions, better aligning the technology and the organization from the start.

There is an existential labor productivity challenge facing manufacturers, driven by mass retirement and turnover. Manufacturers need to get all of their operators performing like seasoned veterans in order to remain competitive. By enabling operators with AI-driven, prescriptive real-time process recommendations, we've seen massive performance improvements across all operators.”

Willem Sundblad, CEO & Co-Founder, Oden Technologies

There are players, such as ClearBlade, that are focusing on providing lean, cost-effective and flexible solutions. IIoT platforms are recognizing that customers need flexibility to be able to have the industrial middleware to connect to the components that they’ve had for decades. In a nutshell, the market needs more managed services that are flexible. More services mean more stickiness. Customers aren’t looking for solutions that take years to build and mature; they need a quick ROI and the ability to grow.

Limitations associated with security, integrity, and privacy of data in connected devices – As the number of connected devices grows, so does the need for data protection and privacy. These devices and networks could include sensitive and personal data that attackers could use. Data exploitation may emerge because of the rising reliance on connected devices, reflecting design flaws and the vulnerabilities of connected devices. Adopting operational technology (OT) security tools into a tech-stacks is one way of combatting some of the vulnerabilities identified.

Difficulty achieving real scalability – Despite widespread piloting of digital initiatives in manufacturing, few organizations have successfully scaled their IIoT use cases to achieve significant operational or financial gains. This "pilot trap" likely stems from the perception of IIoT as a purely technical challenge, often championed by IT and OT specialists. To unlock the true potential of IIoT, leadership commitment is crucial. Players that have successfully implemented IIoT solutions insist that the initiatives transcend departmental boundaries and become company-wide transformation efforts.

Technical obstacles to IIoT – Many organizations wonder, for example, how to overcome the challenges caused by heterogeneous systems and application landscapes, or how to analyze which functions should be supported by which systems (for example, product life-cycle management, enterprise resource planning, manufacturing execution, supply-chain management). Finding a supplier that supports the scale and size of your business is key, and it is helpful to partner with suppliers that are hardware-agnostic and connect to standard industry protocols.

AI will be a game-changer

As previously mentioned, through the implementation of IIoT, operators have been able to access large amounts of factory data. The trouble is that this data has traditionally not been leveraged to its full potential. The rapid development of AI is changing this.

Various applications of industrial data can be made possible through the development and deployment of AI models. The hope is that the data will paint a clearer picture of operations. The end goal is to have data that can start to automate decisions. In this way, we see a shift in the value of IIoT to manufacturers. By leveraging AI, the data captured from IIoT solutions can finally enable industrial settings to become more agile, responsive and cost efficient.

Every company is rapidly evolving into an IoT and AI company which is driving tremendous advancements across industries. Harnessing the power of AI and IoT depends on a solid and robust data foundation that provides good, clean, validated, and relevant data. By leveraging connected devices to gather valuable data and then putting that data in the right place at the right time, companies can realize unprecedented insights and efficiencies. Companies that harness the power of IoT and AI are poised to lead in innovation and operational excellence.”

Christian Meinerding, CEO & Co-founder, HiveMQ

The IIoT ecosystem

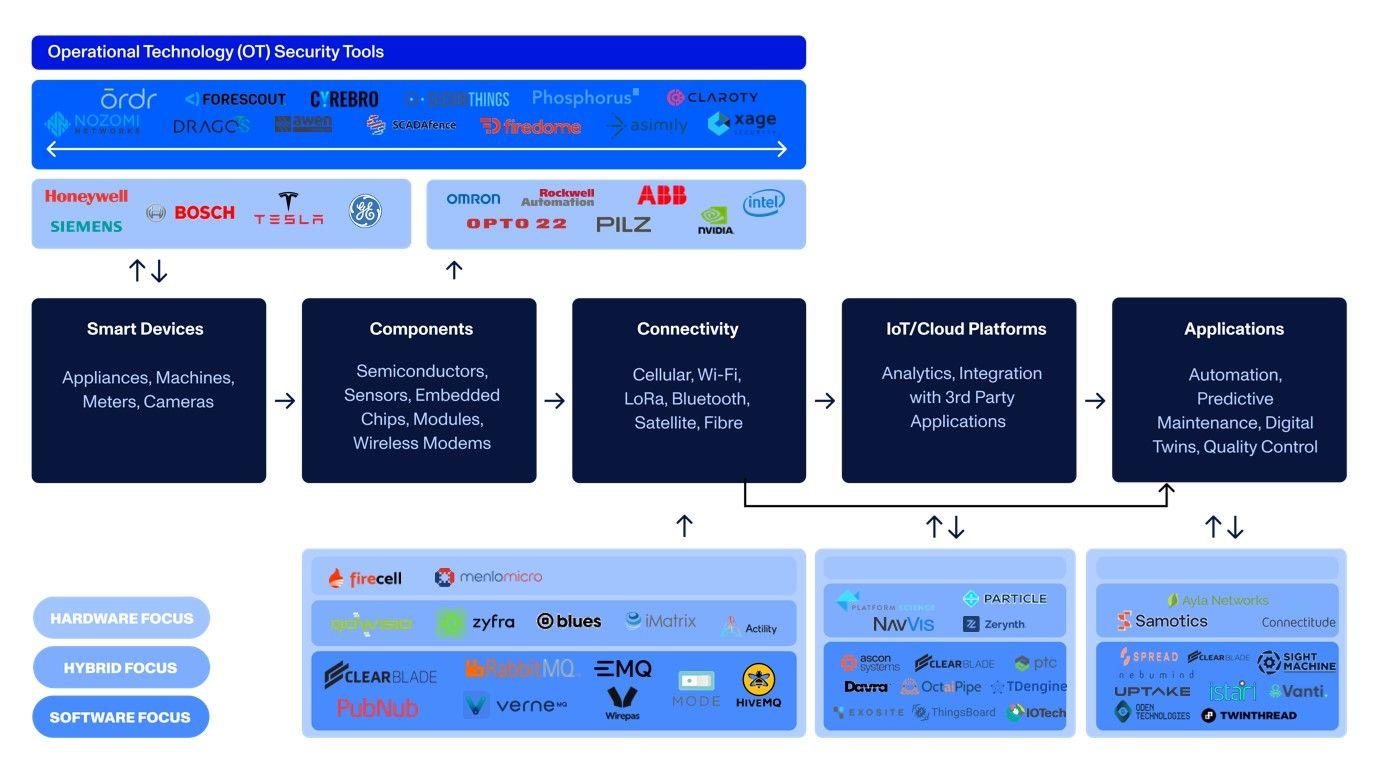

The IIoT ecosystem can be mapped across a value chain to reflect the core modules of IoT. This segmentation includes smart devices, components, connectivity sources, IoT/Cloud Platforms and Applications. In addition, Operational Technology (OT) Security Tools sit on top of the first three links within the chain.

IIoT connectivity refers to the network infrastructure and communication technologies that allow various industrial devices, sensors, machines, and systems to connect and exchange data in an industrial setting. Note that we separate IIoT applications from platforms since applications sit on top of data infrastructure and are able to effectively make use of the data, whilst IIoT platforms operate as data aggregators that facilitate the deployment, management and operation of IIoT systems.

Hardware is an essential element of IIoT, typically in the form of smart devices or components. At Activant we are primarily focused on software-enabled business models and have thus chosen not to consider those players with purely-hardware offerings in as much detail. On the exhibit below we have attempted to lay out the value chain as we see it, and differentiated between hardware, software and hybrid players.

Value Chain

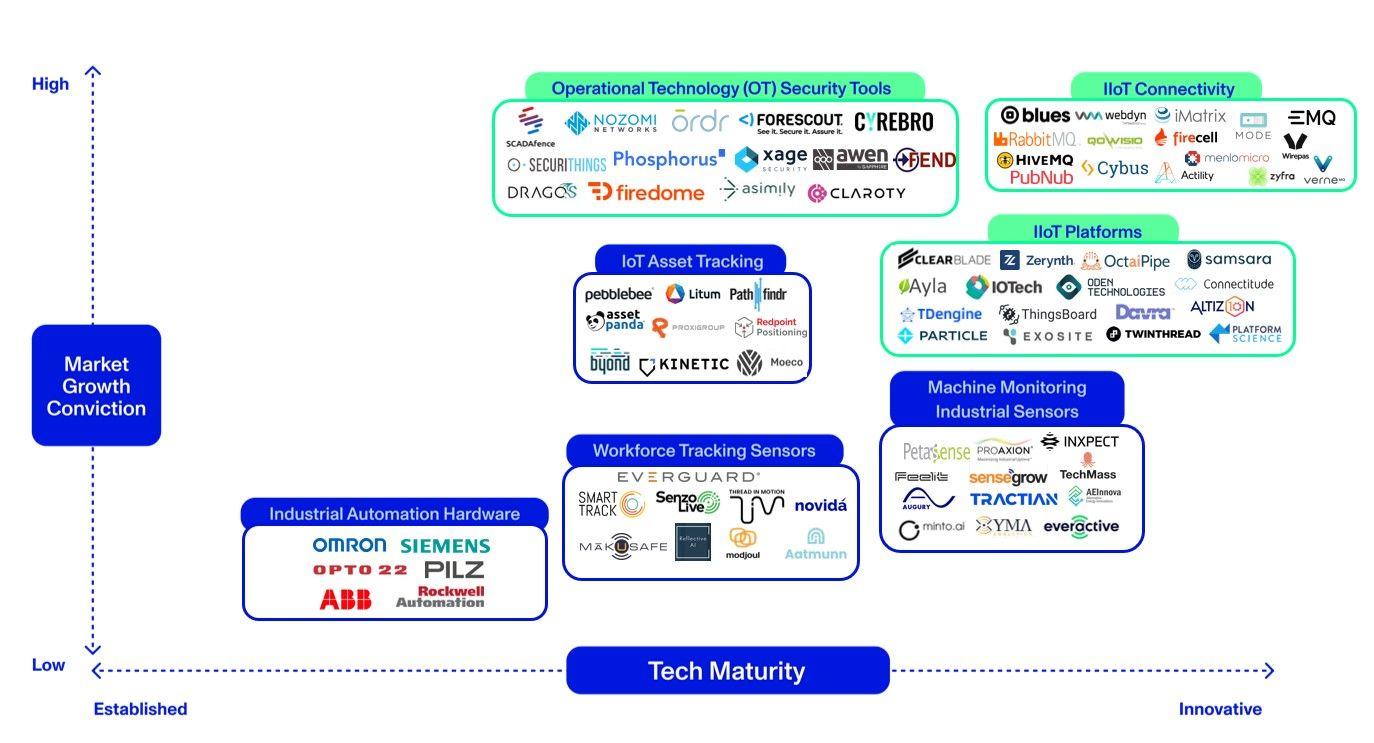

Our View on IIoT

We believe that the answer to the IIoT problem lies in systems that address IIoT connectivity, as well as IIoT platforms themselves, and operational technology (OT) security tools. If IIoT is going to live up to its full potential, these are the solutions that are going to get it there. We depict this on our Activant IIoT Thesis Map.

Activant Thesis Map

Many companies are attempting to change the IIoT landscape but we are most excited by the companies that are focusing on the connectivity layer of IIoT. We see IIoT platforms, the software muscle behind the IIoT operation, as a vital piece of the puzzle and are intrigued by operational technology (OT) security tools.

Thesis Map

Industrial Internet of Things (IIoT)

IIoT Connectivity

This is the foundation that enables all the communication and data processing needed to run industrial applications. It is essentially the network of devices, software, and communication protocols that connect industrial machines, sensors, and other equipment to gather, analyze, and utilize data. We like what Blues and HiveMQ are doing in the space. HiveMQ is a Message Queuing Telemetry Transport (MQTT) Platform, which is essentially the “de-facto standard for IoT messaging”. Blues offers ‘The Notecard’, a developer-friendly, production-ready embeddable chip that enables the collection and delivery of data from any physical device to the cloud (any cloud application). Blues, are at the forefront of the “intelligent edge,” encompassing any company—be it transformers, disruptors, or innovators—that aims to develop intelligent edge products, which of course includes industrials.

IIoT Platforms

IIoT platforms are the “central nervous system” connecting all the industrial devices, collecting data, and transforming it into actionable insights. Manufacturers are taking note of the importance of these platforms. Gartner reported that 25% of large global industrial companies will acquire or invest in an IIoT platform by 2025.14 McKinsey estimates that as a result of strong underlying demand and increasing use-case availability, IIoT spending will increase from $290Bn in 2020 to $500Bn in 2025.15 One notable player within this space is Activant portfolio company Platform Science, a provider of telematics and fleet management solutions to enhance fleet operations and driver experiences.

Clearblade focuses on providing a flexible and secure IoT platform with a platform that works across various systems, networks, protocols and devices. Flexibility is a key buying criteria and market feedback suggests this platform is an attractive option. We were also excited by how Oden Technologies is using IoT for process optimization directly on the factory floor. Their AI-driven software is enabling the manufacturing frontline to achieve peak factory performance. With the challenges around operator shortages, we see these types of tools as vital.

Operational Technology (OT) Security Tools

These tools are specifically designed to safeguard the industrial control systems (ICS) and devices that manage physical processes in critical infrastructure industries like manufacturing, power generation, water treatment, and transportation. Unlike traditional IT security tools focused on data confidentiality, OT security prioritizes the availability, integrity, and reliability of these control systems. We are bullish on the growth of this space, given that approximately 96% of business leaders indicate the need to invest in OT cybersecurity.16 However, we are wary of the implementation challenges that are associated with these tools, with approximately 70% of those who have invested in OT security tools facing implementation challenges.17 One player that stands out is Phosphorus Cybersecurity, a provider of comprehensive security solutions for extended IoT environments.

Final thoughts

Looking at IIoT, we can’t help but draw a comparison to the early days of the internet. There were some initial signs that the internet would be valuable, but this was coupled with lots of scepticism and internet business failures. Once the extensive fiber networks had been laid in the telecom boom, the internet was fast and cheap enough for multiple successful businesses to be born. Similarly, as we see IoT infrastructure becoming more cost-effective and performant, we expect the industry 4.0 use cases to multiply exponentially. We are at the tip of the iceberg when it comes to the applications within the space. The past few years have resulted in us being underwhelmed by IIoT, but we think this is about to change.

IIoT is on track to revolutionize the manufacturing industry. Despite the implementation challenges, we see a large opportunity and many of startups profiled are making IIoT more accessible, easy to implement, and scalable. In addition, the explosion of AI is enabling greater insights to be captured from the data collected from IIoT solutions.

It’s early days for us as we try to navigate this innovative space and mix of companies. We want to learn more from those that are building in the IIoT space. If your solution can make a real difference in the manufacturing environment, contact us!

Endnotes

[1] McKinsey & Company, What are Industry 4.0, the Fourth Industrial Revolution, and 4IR?, 2022

[2] Activant Capital Research, Industrial Intelligence, 2023

[3] Ibid

[4] Ibid

[5] Molten, Molten Ventures leads €40 million Series A in HiveMQ, 2022

[6] YouTube, Meet a Factory Digital Twin from Wistron, 2024

[7] Plant Engineering, The benefits of IIoT predictive condition monitoring for maintenance programs, 2023

[8] Forbes, Manufacturing Without Unplanned Downtime Could Become A Reality Sooner Than You Think, 2021

[9] Plant Engineering, The benefits of IIoT predictive condition monitoring for maintenance programs, 2023

[10] DIGI, IoT in Manufacturing: Applications and Benefits of Smart Factories, 2024

[11] Plant Engineering, The benefits of IIoT predictive condition monitoring for maintenance programs, 2023

[12] McKinsey & Company, Leveraging Industrial IoT and advanced technologies for digital transformation, 2021

[13] Ibid

[14] Nagarro, Choosing the right Industrial IoT (IIoT) strategy to be a resilient Smarter Factory, 2022

[15] McKinsey, Leveraging Industrial IoT and advanced technologies for digital transformation, 2021

[16] McKinsey, How to enhance the cybersecurity of operational technology environments, 2023

[17] Ibid

The information contained herein is provided for informational purposes only and should not be construed as investment advice. The opinions, views, forecasts, performance, estimates, etc. expressed herein are subject to change without notice. Certain statements contained herein reflect the subjective views and opinions of Activant. Past performance is not indicative of future results. No representation is made that any investment will or is likely to achieve its objectives. All investments involve risk and may result in loss. This newsletter does not constitute an offer to sell or a solicitation of an offer to buy any security. Activant does not provide tax or legal advice and you are encouraged to seek the advice of a tax or legal professional regarding your individual circumstances.

This content may not under any circumstances be relied upon when making a decision to invest in any fund or investment, including those managed by Activant. Certain information contained in here has been obtained from third-party sources, including from portfolio companies of funds managed by Activant. While taken from sources believed to be reliable, Activant has not independently verified such information and makes no representations about the current or enduring accuracy of the information or its appropriateness for a given situation.

Activant does not solicit or make its services available to the public. The content provided herein may include information regarding past and/or present portfolio companies or investments managed by Activant, its affiliates and/or personnel. References to specific companies are for illustrative purposes only and do not necessarily reflect Activant investments. It should not be assumed that investments made in the future will have similar characteristics. Please see “full list of investments” at https://activantcapital.com/companies/ for a full list of investments. Any portfolio companies discussed herein should not be assumed to have been profitable. Certain information herein constitutes “forward-looking statements.” All forward-looking statements represent only the intent and belief of Activant as of the date such statements were made. None of Activant or any of its affiliates (i) assumes any responsibility for the accuracy and completeness of any forward-looking statements or (ii) undertakes any obligation to disseminate any updates or revisions to any forward-looking statement contained herein to reflect any change in their expectation with regard thereto or any change in events, conditions or circumstances on which any such statement is based. Due to various risks and uncertainties, actual events or results may differ materially from those reflected or contemplated in such forward-looking statements.